Optical Surface . It is critical that the suppliers and customers have a consistent approach during the inspection process. Most frequently, the components consist of a body of suitable optical material with surfaces worked to present a desired shape and. Determine how to select an optical window based on its material transmission, thermal and mechanical properties, and other specifications. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Surface quality is one of the most scrutinized specifications in the optics industry. To verify the quality of the surface,.

from www.mdpi.com

It is critical that the suppliers and customers have a consistent approach during the inspection process. To verify the quality of the surface,. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Surface quality is one of the most scrutinized specifications in the optics industry. Determine how to select an optical window based on its material transmission, thermal and mechanical properties, and other specifications. Most frequently, the components consist of a body of suitable optical material with surfaces worked to present a desired shape and. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various.

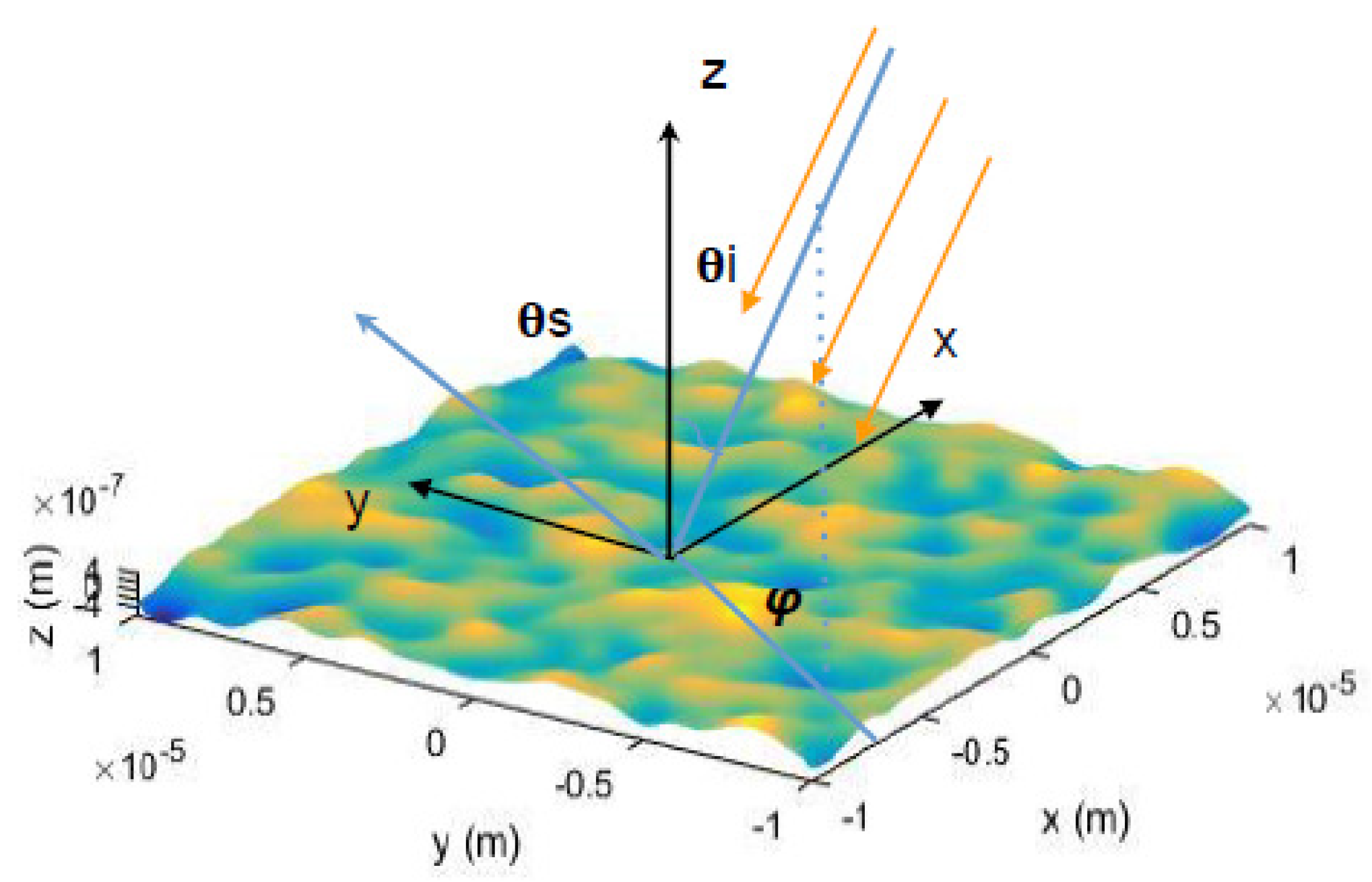

Materials Free FullText Surface Roughness Effects on the Broadband

Optical Surface The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. To verify the quality of the surface,. Most frequently, the components consist of a body of suitable optical material with surfaces worked to present a desired shape and. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. It is critical that the suppliers and customers have a consistent approach during the inspection process. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Determine how to select an optical window based on its material transmission, thermal and mechanical properties, and other specifications. Surface quality is one of the most scrutinized specifications in the optics industry. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various.

From www.neaspec.com

Characterization of optical surface waves neaspec GmbH Optical Surface Surface quality is one of the most scrutinized specifications in the optics industry. It is critical that the suppliers and customers have a consistent approach during the inspection process. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise. Optical Surface.

From kimmy.fi

Tabletop optical surface profiler Kimmy Photonics Optical Surface Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. Surface quality is one of the most scrutinized specifications in the optics industry. It is critical that the suppliers and customers have a consistent approach during the inspection process. To verify the quality of the surface,.. Optical Surface.

From centerfreeformoptics.org

OCT Adapted for Freeform Optical Metrology The Center for Freeform Optics Optical Surface Surface quality is one of the most scrutinized specifications in the optics industry. Most frequently, the components consist of a body of suitable optical material with surfaces worked to present a desired shape and. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. It is. Optical Surface.

From telescope-optics.net

Tests for optical surface quality Optical Surface To verify the quality of the surface,. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. It is critical that the suppliers and customers have a consistent approach during the inspection process. Most frequently, the components consist of a body of suitable optical material with. Optical Surface.

From www.meddeviceonline.com

ZeGage™ 3D Optical Surface Profiler Optical Surface An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Determine how to select an optical window based on its material transmission, thermal and mechanical properties, and other specifications. To verify the quality of the surface,. Optical. Optical Surface.

From www.spiedigitallibrary.org

Review of optical freeform surface representation technique and its Optical Surface Surface quality is one of the most scrutinized specifications in the optics industry. It is critical that the suppliers and customers have a consistent approach during the inspection process. To verify the quality of the surface,. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. Most frequently, the components consist of a body. Optical Surface.

From www.researchgate.net

Areal surface roughness measured by noncontact optical profilometer; a Optical Surface Determine how to select an optical window based on its material transmission, thermal and mechanical properties, and other specifications. It is critical that the suppliers and customers have a consistent approach during the inspection process. Surface quality is one of the most scrutinized specifications in the optics industry. An optical component’s surface is designed to achieve a particular set of. Optical Surface.

From physicsworld.com

Optical surface tracker monitors patient position during brain Optical Surface Surface quality is one of the most scrutinized specifications in the optics industry. To verify the quality of the surface,. It is critical that the suppliers and customers have a consistent approach during the inspection process. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. An optical component’s surface is designed to. Optical Surface.

From spie.org

A new test for optical surfaces Optical Surface The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. Surface quality is one of the most scrutinized specifications in the optics industry. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors,. Optical Surface.

From www.photonicsonline.com

ZeGage™ Plus 3D Optical Surface Profiler Optical Surface To verify the quality of the surface,. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. It is critical that the suppliers and customers have a consistent approach during the inspection process. Determine how to select an optical window based on its material transmission, thermal. Optical Surface.

From www.electrooptics.com

Unlock the secrets of optical surface roughness Electro Optics Optical Surface The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Most frequently, the components consist of a body of suitable optical material with surfaces worked to present a desired shape and. Determine how to select an optical window based on its material transmission, thermal and mechanical properties, and other specifications. Optical surfaces, pivotal. Optical Surface.

From www.zygo.com

3D Optical Surface Profilers Profilometers ZYGO Optical Surface The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. It is critical that the suppliers and customers have a consistent approach during the inspection process. To verify the quality of the surface,. Surface quality is one. Optical Surface.

From www.mdpi.com

Materials Free FullText Surface Roughness Effects on the Broadband Optical Surface The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. An optical component’s surface is designed to achieve a particular set of optical and mechanical properties. Determine how to. Optical Surface.

From www.laserfocusworld.com

Optical surface analyzer inspects transparent wafers Laser Focus World Optical Surface The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. It is critical that the suppliers and customers have a consistent approach during the inspection process. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. An optical component’s. Optical Surface.

From blog.redlux.net

Understanding Optical Surface Quality MILPRF13830B (MILO13830 Optical Surface Most frequently, the components consist of a body of suitable optical material with surfaces worked to present a desired shape and. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Determine how to select an optical window based on its material transmission, thermal and mechanical properties, and other specifications. Optical surfaces, pivotal. Optical Surface.

From www.youtube.com

Leica DCM8 Optical Surface Metrology System Introduction YouTube Optical Surface Surface quality is one of the most scrutinized specifications in the optics industry. To verify the quality of the surface,. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. It is critical that the suppliers and customers have a consistent approach during the inspection process.. Optical Surface.

From blog.redlux.net

How to Interpret the Optical Surface Quality Standards Redlux Optical Surface Surface quality is one of the most scrutinized specifications in the optics industry. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. To verify the quality of the. Optical Surface.

From www.techbriefs.com

High Quality Optical Surfaces Tech Briefs Optical Surface It is critical that the suppliers and customers have a consistent approach during the inspection process. Optical surfaces, pivotal in the realm of optical components such as lenses and mirrors, are governed by stringent specifications ensuring optimal performance across various. The techniques in surface metrology with the largest diversity are based on electrodynamics, more precise on the. Most frequently, the. Optical Surface.